CORPORATE

Taking steps towards increasing onshore manufacturing

At Workwear Group, we’re thrilled to partner with offshore suppliers who are looking to expand their manufacturing efforts in Australia. By taking steps towards increasing onshore manufacturing, we’re presented with the flexibility to improve lead times, exceed customer expectations, and create onshore job opportunities.

At Workwear Group, we’re thrilled to partner with offshore suppliers who are looking to expand their manufacturing efforts in Australia. By taking steps towards increasing onshore manufacturing, we’re presented with the flexibility to improve lead times, exceed customer expectations, and create onshore job opportunities.

Last month, our General Manager of Uniforms and Operations, Matt Blashki, was approached by Ragtrader to discuss Workwear Group’s local manufacturing efforts. You can read the article below:

ragtrader.com.au

Christopher Kelly | 1 September 2023

Australian uniform business Workwear Group is partnering with offshore suppliers in a bid to expand local manufacturing capabilities.

General Manager of Uniforms and Operations Matt Blashki confirmed the news with Ragtrader, noting his team is currently in discussion with two offshore suppliers.

“These businesses are already long-term partners who are interested in supporting us on shore, so we’re excited at the prospect of being able to extend our local output with their expertise,” Blashki said.

“We believe these potential sites will increase capacity for local production and lift the capability of Australian manufacturing.”

Blashki said if the discussions are successful, Workwear Group will increase the number of units it makes in Australia and potentially shorten lead times within its supply chain.

Last financial year, Workwear Group manufactured and procured close to one million clothing items locally. Australia is the company’s third-largest manufacturing supply country, according to Blashki, with overseas suppliers in countries such as Europe, South East Asia and China.

Workwear Group owns the brands Hard Yakka, KingGee and NNT Uniforms, alongside its Workwear Group Uniforms business.

Its uniforms business services over 150 clients across Australia and New Zealand, including Qantas, ANZ, Westpac, Australia Post, Ambulance Victoria, Queensland Health and Australian Defence Force.

Blashki said there is growing interest in onshore manufacturing across its client base that is driving Workwear Group’s plans to expand local manufacturing.

“With the uniforms sector of our business currently responding to the bulk of this [local] output, there is an opportunity to expand local manufacturing further into our brands in the future,” he said.

“We have a clear strategic plan to actively grow capacity and capability further, including Indigenous participation, with the support of our current and future customers.

“Products made in Australia are primarily for Australian customers wanting Australian made goods. We’re responding to their preference for uniforms and workwear to be locally made.”

In recent months, Workwear Group added three internal roles that are solely focused on delivering local manufacturing. Blashki said the company has intentionally built this expertise to support its local manufacturing growth.

“We have a view to add more depending on customer expectations and appetite for local growth,” he said. “We’ll be working closely with our suppliers on how local jobs will increase for the specific skills needed to increase local capacity and capability.

“By working with the right people, we intend to support local manufacturing to develop further and become a stronger customer proposition and workplace.”

Blashki said while a significant amount of Uniforms product requested comes from its branded catalogue products, Workwear Group also work closely with each client to understand their needs and create custom ranges for them via an in-house design team.

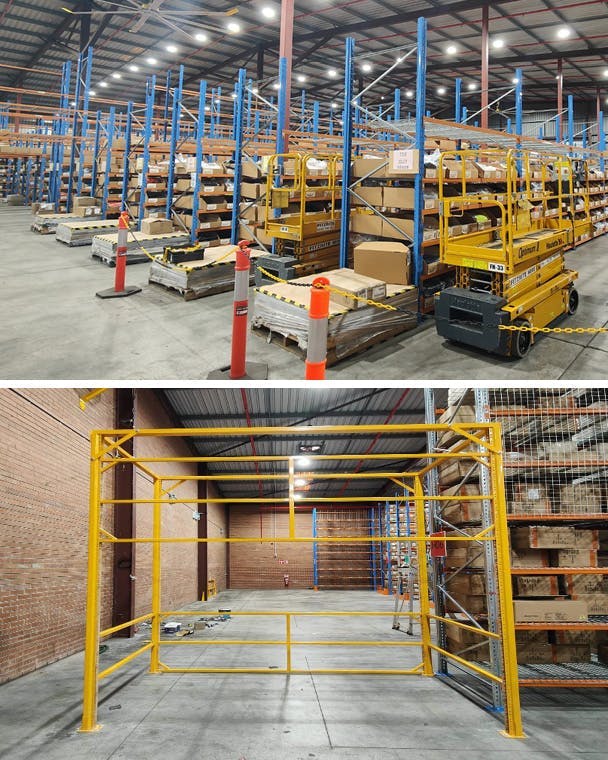

Meanwhile, the company has upgraded its warehouse in Welshpool, Western Australia.

Blashki said Workwear Group initially identified areas within its Welshpool warehouse that were not effectively utilised.

“Mindful of cost efficiency, we undertook a thorough evaluation and reconfiguration process,” he said.

“The result has seen a 30% capacity uplift, improved delivery times for customers, safety improvements for people and machinery and strengthened our overall on-shore logistics proposition.”

Workwear Group has four warehouses overall, with the other three in Queensland, Victoria, and New Zealand.

CORPORATE

Increased Capacity at our Welshpool Warehouse

Workwear Group is proud to announce we’ve recently increased capacity at our Welshpool warehouse in Western Australia.

Read More

SUSTAINABILITY

Unveiling Workwear Group’s New Packaging Standard, Designed to Reduce Waste and Minimise Single-Use Plastic

Workwear Group (WWG) is committed to reducing our environmental footprint by looking for new ways to reduce waste and packaging across our brands.

Read More